BIJUR DELIMON INTERNATIONAL provides a wide range of reliable lubrication products and components for almost any industrial application.

Our offering of industrial products is formidable; heavy-duty grease systems, oil recirculating systems, light and heavy duty oil systems, mobile on and off-road fluid grease applicators, single point feeders, cooling and chilling units – and more. With a product offering like ours, Bijur Delimon stands ready to assist you in formulating the right plan for the right application be it a steel mill, oil refinery, truck chassis, earthmover, packaging or plastics machine, machine tool, conveyor, assembly machine, wind turbine generator, printing press, textile machine, food and beverage processor or a simple pillow block.

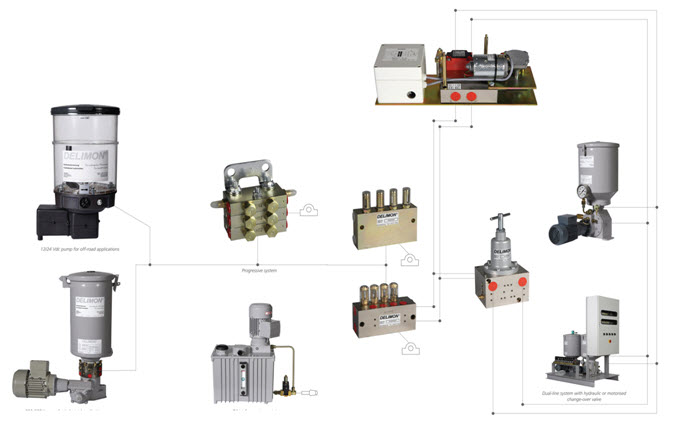

Products types :-

|

The FZ-A type lubricator is a central plunger grease pump, which is operating without valves and springs. The FZ-A type grease lubricator is intended mainly for multiple systems, i.e., in systems with up to a maximum of 12 lubrication points no additional distributor is required. The numerous ratios available. Permissible feed pressure up to 250 bar, Delivery volume per outlet and hours max. 60 ccm. This can be adjusting spindles. |

|

The BS-B lubricator is used in cases where a lot of lubrication points shall centrally and reliably be supplied with lubricant. In connection with ZV-B distributors, the pump is predominantly used in dual-line lubrication. Discharge pressure adjustable 400 bar, Max rpm 250 min. |

|

The BM-B pump, because of is constructional characteristics, may be used in single line-, dual line-, progressive and spray lubricating systems.Regardless of the number of lubrication points, the pump can be effectively adapted to meet any requirements. It can also be used for refilling and mobile greasing systems. |

|

|

|

Pump BF-ESuitable everywhere lubrication grease is to be fed with high pressure straight from the barrel |

The barrel pump BF-G is adapted to take the grease of penetration class 000 up to 2 straight from a 50 l and 210 litre barrel (DIN 6644 -2 / - 4 and DIN EN 13008). |

|

Autolub-M in the sector of plants and machinery: Machine tools, presses, punching machines, shears hoisting plants, water pumps etc. Discharge pressure max 250 bar, numbers of pump elements 1 up to 5 pieces, gear reductions 60:1 |

|

The DYNAMIS pump was designed and developed to serve as a multi-function automatic lubricant pump, Due to its compact size and modular design, the pump can easily be modified for use in wind turbine power stations, general industry, commercial vehicle and spraying applications. |

|

The distributors ZV-B are used for dual-line central lubrication systems for grease and for oil. Their function is to meter the lubricant and to press it through the lines to the lubrication points independently of back pressure. |

|

The major element of a progressive system is the lubricant distributor. Distributors ZP-A are used to divide and meter lubricant in total loss central lubrication systems (oil, liquid grease and grease) and in oil recirculation systems suitable for small, medium and large machine plants. |

|

The distributors ZV-C are used for dual-line central lubrication systems for grease and for oil. Their function is to meter the lubricant and to press it through the lines to the lubrication points independently of back pressure |

|

The distributors ZV-F are used for dual-line central lubrication systems for grease and for oil. Their function is to meter the lubricant and to press it through the lines to the lubrication points independently of back pressure. |

|

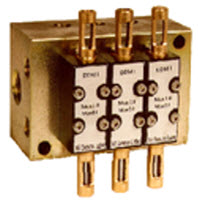

DDM Modular dual line valves are ideal for applications where a range of lubrication amounts is needed from a single block. All the moving parts are in the module. The module connects to a manifold (2 to 20 outlets). The DDM/SDM dual line modules can be replaced individually so you don't have to change an entire block in the event of a malfunction. |

|

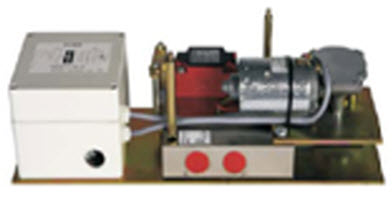

For hydraulic systems, particularly dual-line centralized systems. For use SA-V as 3/2-way valve close outlet B. SA-V is Function 4/2-way, Drive by direct-current geared motor and Working pressure max. 400 bar |

|

The switching device SG-A is used as differential pressure switch in dual-line centralized lubrication system. When the differtial pressure is 50 bar and/or 100 bar, it releases a pulse for the reversion of the directional control valve or for the monitoring of the system. |

|

The pressure gauge set is suitable for two-line central lubrication systems. It enables a visual check to be made of the lubricant pressure, or the pressure difference between the two main lines. |

|

The Solenoid valve is electrically-operated and is used to open or close lubrication lines for zone systems, alternating system pumps and other applications where a user needs automatic operation. A D05 subplate with mounting bolts is included. When mounted to a D05 subplate standard configuration is normally closed. |

|

Control units are oil proportioning devices for continuous systems. Each outlet of a lubrication system is controlled by a control unit. The lubricator in the system dispenses known amounts of oil to the distribution network and control units deliver this oil in varying amounts the bearing points. |

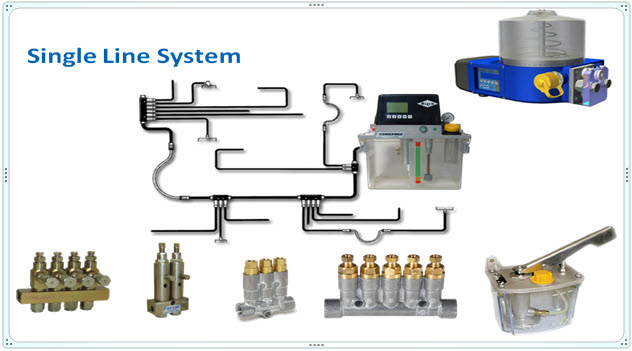

system types :-

| ** single line system . | ** Oil fog system. |

| ** Dual line system . | ** Air- oil lubrication system |

| ** Multi line system . | ** Spray lubrication system |

| * * Progressive system . | ** Oil recirculation system. |

| ** Rail way lubricant. | ** Chain lubrication system |